Hollow Glass Sphere HL38

- HL38

- 0.36-0.40g/cm³

- 0.19-0.22g/cm³

- D50 ≤40μm

- D90 ≤65μm

- 38MPa / 5500PSI

Specification

| Type |

True Density (g/cm³) |

Bulk Density (g/cm³) |

Compressive Strength (Mpa/Psi) |

D50 (µm) |

D90 Typical Value (µm) |

Application |

| HL15 | 0.13-0.17 | 0.08-0.09 | 4/500 | 85 | 120 | Epoxy Tooling Board, Solid Buoyancy Materials(SBM), Emulsion Explosives, Car Repair Putty, Paints and Coatings |

| HL20 | 0.18-0.22 | 0.10-0.12 | 4/500 | 65 | 110 | Epoxy Tooling Board, Solid Buoyancy Materials(SBM), Emulsion Explosives, Car Repair Putty, Paints and Coatings |

| HL25 | 0.23-0.27 | 0.13-0.15 | 5/750 | 65 | 100 | Thermal Insulation Coatings, Sealants and Adhesives, Solid Buoyancy Materials(SBM) |

| HL30 | 0.28-0.32 | 0.15-0.18 | 10/1500 | 55 | 85 | Thermal Insulation Coatings, Solid Buoyancy Materials(SBM) |

| HL32 | 0.30-0.34 | 0.17-0.19 | 14/2000 | 45 | 80 | Paints and Coatings, SMC/BMC, Sealants and Adhesives, Putty |

| HL35 | 0.33-0.37 | 0.18-0.21 | 21/3000 | 40 | 70 | Cementing Slurry, Low Density Drilling Fluids |

| HL38 | 0.36-0.40 | 0.19-0.22 | 38/5500 | 40 | 65 | Paints and Coatings, SMC/BMC, Automotive Underbody Coating, Solid Buoyancy Materials(SBM) |

| HL40 | 0.38-0.42 | 0.19-0.23 | 28/4000 | 40 | 70 | Cementing Slurry, Low Density Drilling Fluids,Thermal Insulation Coatings |

| HL42 | 0.40-0.44 | 0.21-0.24 | 55/8000 | 40 | 60 | Cementing Slurry, Low Density Drilling Fluids |

| HL46 | 0.44-0.48 | 0.23-0.26 | 41/6000 | 40 | 70 | Cementing Slurry, Low Density Drilling Fluids, SMC/BMC |

| HL50 | 0.48-0.52 | 0.25-0.27 | 55/8000 | 40 | 60 | Cementing Slurry, Low Density Drilling Fluids |

| HL60 | 0.58-0.62 | 0.29-0.34 | 83/12000 | 40 | 65 | Cementing Slurry, Low Density Drilling Fluids |

| HL60S | 0.58-0.63 | 0.30-0.34 | 124/18000 | 35 | 55 | Cementing Slurry, Low Density Drilling Fluids |

| HS20 | 0.18-0.22 | 0.10-0.12 | 7/1000 | 60 | 90 | Epoxy Tooling Board, Solid Buoyancy Materials(SBM) |

| HS22 | 0.20-0.24 | 0.11-0.13 | 8/1200 | 45 | 70 | Epoxy Tooling Board, Solid Buoyancy Materials(SBM), Emulsion Explosives, Car Repair Putty, Paints and Coatings |

| HS28 | 0.27-0.30 | 0.15-0.17 | 28/4000 | 45 | 65 | Solid Buoyancy Materials(SBM), SMC,Sealants and Adhesives |

| HS38 | 0.36-0.40 | 0.19-0.22 | 38/5500 | 30 | 50 | Composite Circuit Board, SMC,Sealants and Adhesives |

| HS42 | 0.40-0.44 | 0.21-0.24 | 55/8000 | 25 | 40 | Rubber, Shoe Material, Sealants and Adhesives, SMC, Cementing Slurry |

| HS46 | 0.44-0.50 | 0.22-0.25 | 110/16000 | 20 | 30 | 5G Related Plastic, Engineering Plastic |

| HS60 | 0.58-0.62 | 0.29-0.33 | 193/28000 | 16 | 25 | 5G Related Plastic, Engineering Plastic |

| HS65 | 0.63-0.67 | 0.30-0.33 | 207/30000 | 13 | 20 | 5G Related Plastic, Engineering Plastic |

| HS70 | 0.75-0.80 | 0.33-0.35 | 207/30000 | 10 | 15 | 5G Related Plastic, Engineering Plastic |

| HM10 | 1.50-1.60 | 0.40-0.43 | 193/28000 | 5 | 10 | |

| HM15 | 1.30-1.40 | 0.39-0.42 | 124/18000 | 10 | 15 | |

| HM20 | 1.00-1.10 | 0.38-0.40 | 124/18000 | 12 | 20 | |

| HM30 | 0.80-0.90 | 0.34-0.37 | 83/12000 | 20 | 30 | |

| HM30A | 1.00-1.10 | 0.38-0.40 | 83/12000 | 12 | 30 |

Product Description

Hollow Glass Microspheres is a kind of hollow spherical powdered ultralight inorganic nonmetallic materials.

The Properties of Hollow Glass Microsphere :

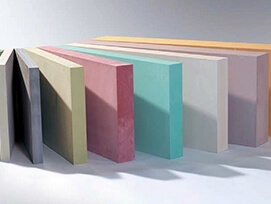

Pure white color, Hollow Microspheres can be widely used in products which have high requirements for looks and colors.

Low density, reducing the products’basic weight obviously after filling. (the density of HGS is one out of a dozen of traditional filler particles' density). Relatively large volume, which can substitute and save more resins, reducing cost.

High dispersion and good fluidity, dimensional stability, reduced warpage and shrinkage when used as additives.

Heat insulation, sound insulation, mostly used as heat insulation paints and coatings, automotive sealants.

In addition, corrosion resistant, fire resistant, non-conducting.

Application Area

a. lightweight cement, low-density oil well cementing slurry & low-density drilling fluids additive.

b. low-density FRP(fiberglass-reinforced plastic), SMC, BMC composites.

c. Nylon, PA, PA6, PA66 for reducing weight.

d. low-density adhesives & sealants.

e. heat insulation paints and coatings.

f. Construction (reducing warpage/shrinkage).

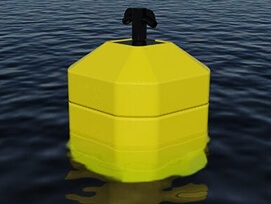

g. Insulation and Buoyancy.

h. artificial marble.

We are the biggest glass microbeads supplier of CHINA, and have more than 30 types of hollow glass spheres for sale. Our hollow microspheres can be used in paint and coatings, construction sealant, rubber, plastic, FRP, artificial stone, putty and other products as filler and weight-reducing agent. The microballoons can also be used to produce high-strength, low-density cement slurry and low-density drilling fluid in oil and gas extraction industry. more and more industries now trying to testing the microballoons as additives to improve their products' properties.

Related Applications

Application of Hollow Glass Sphere in Drilling Fluids and Cementing Slurry

Application of Hollow Glass Sphere in Plastic PA6 PA66

Application of Hollow Glass Sphere in Sealants and Adhesives

Application of Hollow Glass Sphere in Epoxy Tooling Board

Application of Hollow Glass Sphere in Marine Buoyancy Modules

Application of Hollow Glass Sphere in Thermal Insulation paints

Application of Hollow Glass Sphere in Emulsion Explosives

contact us

We will store the information you have provided us. We will only use this information for the purpose of helping to answer your inquiries. We will not disclose your information to third parties.