News

Physical characterization of Hollow Glass Sphere and the relationship between the physical properties

Release time:

2023-03-21

Hollow Glass Sphere is a kind of micro-scale Hollow Glass Sphere with smooth surface, and its appearance is white fluidity powder. The physical parameters of Hollow Glass Sphere are mainly density, particle size and particle size distribution, compressive strength and so on. Understanding the meaning of the physical parameters of Hollow Glass Sphere and the relationship between the physical properties will help us to better understand and use the products.

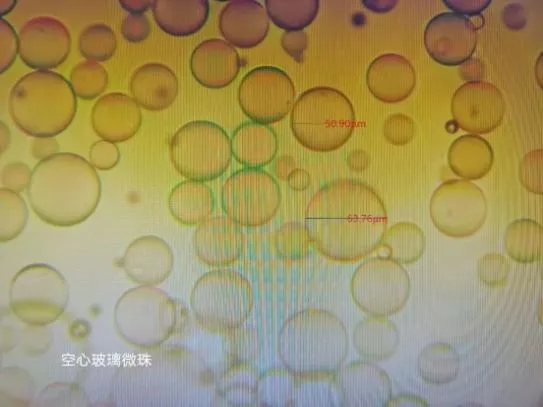

Fig.1 Microscope photograph of Hollow Glass Sphere

1. density

Density refers to the mass per unit volume of a substance. In calculation, density is the quotient of mass divided by volume, that is, the ratio of mass to volume of a substance.

True density, referred to as true density, refers to the density of a substance after removing internal pores or gaps between particles. Hollow Glass Sphere are closed spheres, and their true density is the density after removing the voids between the spheres.

Bulk density refers to the mass per unit volume of the powder material in the natural accumulation state. Calculatively, the bulk density is the mass of the powder divided by the volume of the container occupied by the powder. Density calculated as natural bulk volume is also known as loose density, and as tapped volume is known as tapped density. Since the volume (bulk volume) of the container occupied by the powder includes voids between the powders, the bulk density is usually smaller than the true density. The bulk density of Hollow Glass Sphere is about half of the true density.

The true density of spheres can be measured quickly and accurately by using a gas displacement true density analyzer.

The true density can guide our product application and composite material formulation design, while the bulk density has guiding significance for powder packaging and transportation. The true density of Hollow Glass Sphere is 0.12-1.6g/cm3, which is about 1/5-1/10 of that of traditional powder materials. For products of the same quality, the volume space occupied by Hollow Glass Sphere is much larger than that of traditional powder materials. Appropriate packaging can be more economical and environmentally friendly transport of goods, while reducing the space occupied by the goods in the warehouse.

2. particle size and size distribution

Powder is a collection of small particles of different sizes, and the size of the particles is called the particle size or particle size. Hollow Glass Sphere are spherical particles, and the diameter of the sphere is the particle size.

Particle size distribution refers to the percentage of particles with different particle sizes in the total powder, and there are two forms of interval distribution and cumulative distribution.

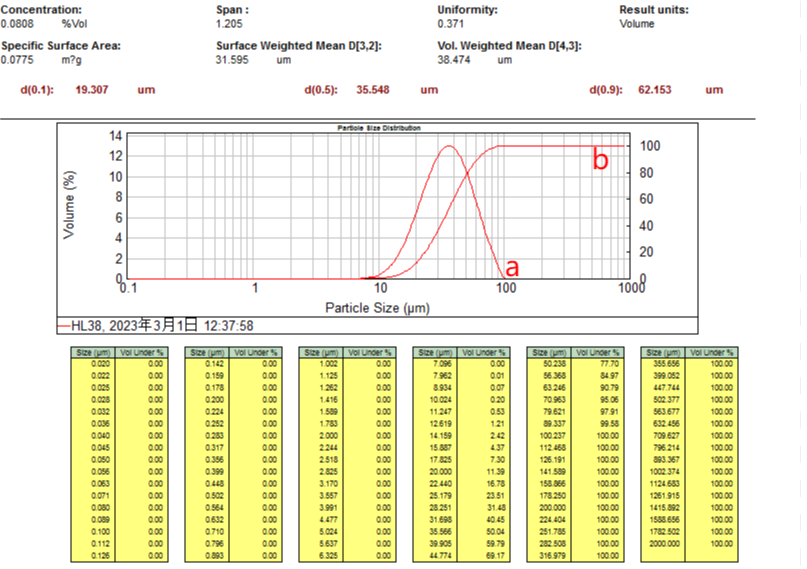

Interval distribution, also known as differential distribution or frequency distribution, represents the percentage content of particles in a series of particle size intervals. In Figure 2 below, the curve (a) is the particle size interval distribution curve of the St. Wright Hollow Glass Sphere HL38, on which the left-hand ordinate value corresponding to the horizontal coordinate particle size value is not the percentage content corresponding to the particle size, but the first-order derivative of the particle percentage content to the particle size.

Cumulative distribution is also called integral distribution, which indicates the percentage content of particles less than or equal to a certain particle size. In Figure 2 below, the curve (B) is the cumulative distribution curve of HL38, and the vertical coordinate value on the right side is the cumulative percentage content corresponding to the horizontal coordinate particle size, that is, the percentage content of particles less than or equal to the particle size value, or the percentage content of particles below the particle size value.

In our regular test report, the cumulative distribution data of several typical particle sizes are: D10/D50/D90:

D50 refers to the particle size corresponding to a sample when the cumulative particle size distribution percentage reaches 50%, with particles smaller than it accounting for 50% and particles larger than it accounting for 50%. D50 is also called median particle size.

D90 refers to the particle size corresponding to 90% of the cumulative particle size distribution of a sample, and 90% of the particles with a particle size smaller than it.

Similarly, D10 refers to the particle size corresponding to a sample when the cumulative particle size distribution percentage reaches 10%, and the particles larger than it account for 90%.

The particle size distribution of Hollow Glass Sphere is based on the volume-based percentage distribution, and the value corresponding to D90 we refer to represents the particle size value corresponding to 90% of the cumulative particle size volume percentage, that is, the particles below the particle size account for 90% of the total volume. HOLLOWLITE uses a laser particle size analyzer to test the particle size distribution of Hollow Glass Sphere.

Fig.2 Size distribution of HOLLOWLITE Hollow Glass Sphere HL38

3. compressive strength

Compressive strength refers to the isostatic strength corresponding to a certain value of the broken rate of Hollow Glass Sphere. The crushing rate refers to the volume percentage of the broken Hollow Glass Sphere in the total under a certain isostatic pressure.

Compressive strength characterizes the ability of Hollow Glass Sphere to withstand strong isostatic pressure, high compressive strength products, applications can better maintain the hollow structure, product breakage rate is low, in the production and processing to obtain the ideal performance of composite materials.

The compressive strength tester is used to test the compressive strength of the product. The sample is placed in a high-pressure chamber and pressurized with nitrogen. The density of the sample before and after pressurization is tested. The crushing rate is obtained by calculating the change of the sample volume before and after pressurization.

In the production and processing of composite materials, the addition method of Hollow Glass Sphere and the working conditions of the equipment may affect the application effect of Hollow Glass Sphere. We should debug the working conditions of the equipment to make the broken rate as low as possible.

4. density, particle size and size distribution, compressive strength

There is a certain correlation between the density, particle size and compressive strength of Hollow Glass Sphere. The wall thickness of the spheres has some influence on the parameters. In general, the larger the particle size, the larger the volume of the spheres, the smaller the density of the spheres, the lower the compressive strength; on the contrary, the smaller the particle size, the greater the density of the spheres, the higher the compressive strength. Therefore, in general, the particle size of low-density products is larger and the strength is lower; the particle size of high-density products is smaller and the strength is higher. The particle size distribution also has a certain influence on the compressive strength. Usually, the products with narrow particle size distribution have higher compressive strength, which also makes the composite materials have better performance.

The density, particle size and compressive strength of Hollow Glass Sphere are controlled by the production process. In practical applications, sometimes we need products with specific density and particle size, and sometimes we need low-density products with small particle size and high strength. At the same time, The development of composite material application technology also puts forward higher requirements on product performance. HOLLOWLITE will continue to develop new products and produce more high-performance products based on market demand and customer satisfaction.

Related News