Application

Hollow Glass Sphere are widely used in reflective thermal insulation coatings, giving reflective thermal insulation coatings special functions. The reflective heat insulation coating becomes a new type of cooling coating, which has the functions of reflection, radiation and hollow microsphere heat insulation. The coating can efficiently reflect solar infrared and ultraviolet rays in the range of 400nm-2500nm, prevent the heat of the sun from accumulating and heating up the surface of the object, and can automatically carry out heat radiation and cooling, and radiate the heat on the surface of the object into the air to reduce the temperature of the object. At present, this kind of reflective thermal insulation coating is not only used in military and aerospace equipment, but also widely used in oil pipelines, oil storage tanks, communication base stations, large grain storage and other industries.

Learn More

Hollow Glass Sphere are inorganic non-metallic oxides, which are weakly alkaline and very stable in nature. They can be added to various existing mud systems without reacting with various chemicals in the mud, which can ensure the chemical stability of drilling fluid.

Learn More

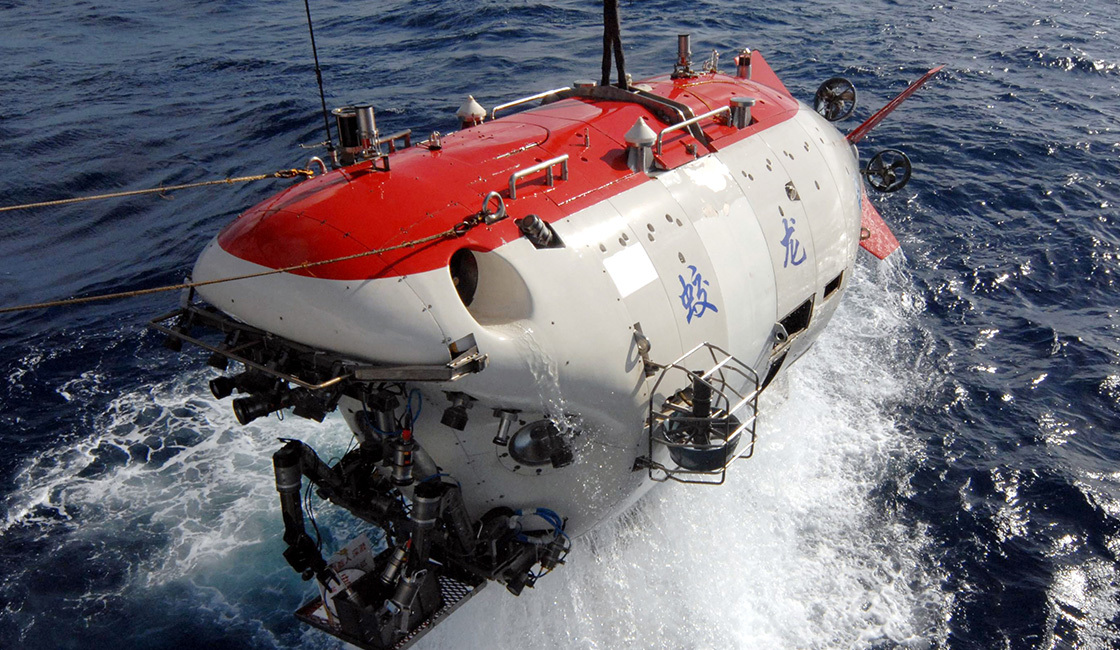

Hollow glass microspheres are very suitable for solid buoyancy materials as lightweight fillers with low density and high strength. Its main application characteristics are:

Learn More

1) Low density; 2) Low dielectric constant; 3) Heat insulation; 4) Prevent material cracking.

Learn More

The addition of hollow glass microspheres can reduce the density, effectively control the thickness of the adhesive layer, reduce shrinkage and cracking, and give it heat insulation, sound insulation and other properties. Silicones, epoxy resins, acrylics, urethanes and the like may be added. According to the type of adhesive and application scenarios, Hollowlite can recommend special surface treatment hollow glass spheres to meet customers different needs.

Learn More

5G communication uses millimeter wave, short wavelength, poor diffraction ability, large attenuation in the propagation process, so it is necessary to reduce the dielectric constant and dielectric loss of the material to improve signal transmission speed and efficiency, reduce delay and loss. Because of its low dielectric constant and dielectric loss, hollow glass microspheres can be added to the substrate as a low dielectric filler to improve the dielectric properties of the product. It can be widely used in materials such as 5G base stations and radomes, 5G mobile phone frames and backplanes, and IoT devices.

Learn More

Hollow Glass Sphere are a cutting-edge new material, which is of great significance to improve the performance of thermoplastic and thermosetting composite materials, lightweight material strategy, energy saving and environmental protection. Compared to regular plastics with mineral powder, Hollow Glass Sphere are used in resins to give plastics a series of excellent properties:

Learn More

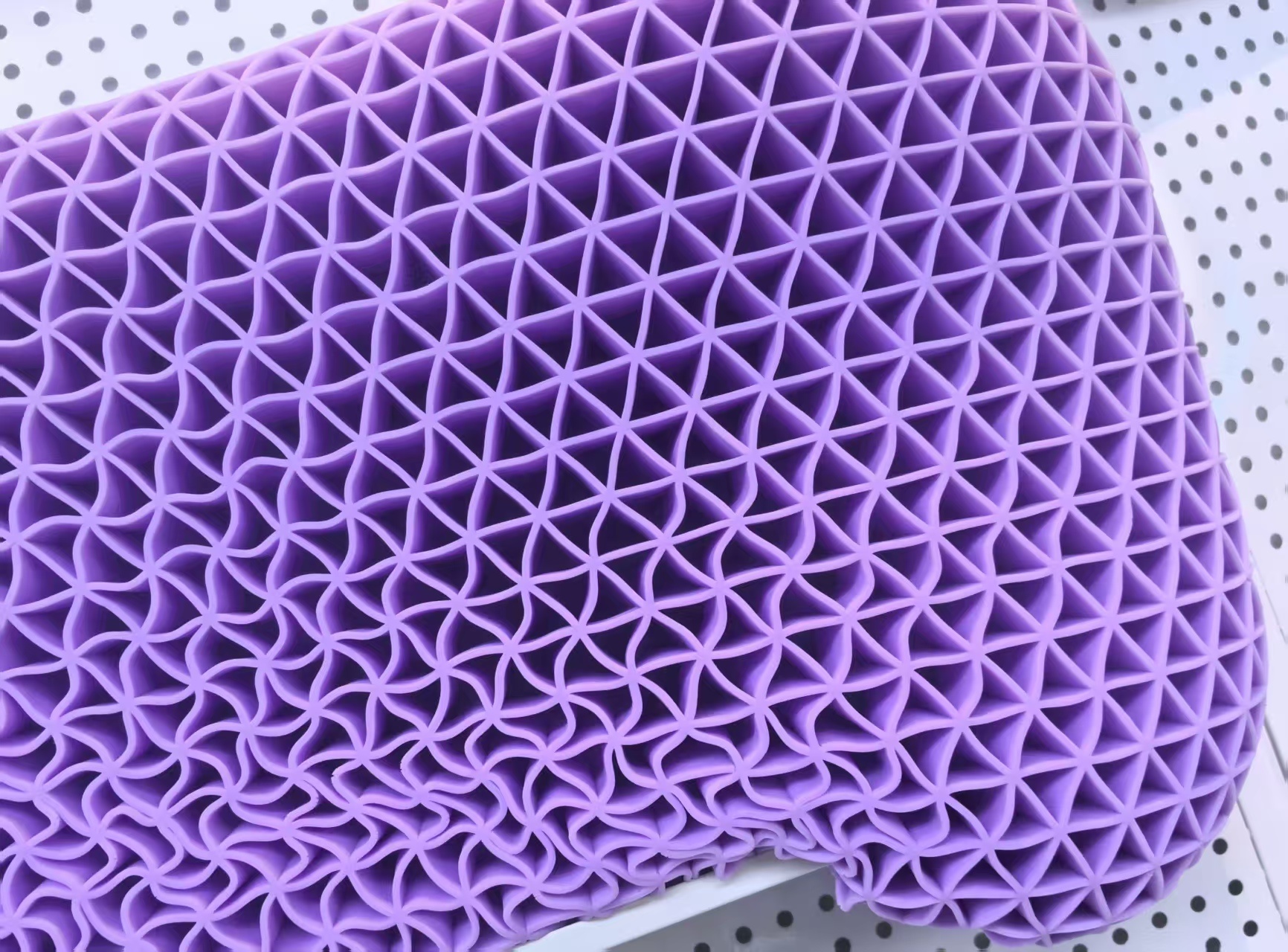

Hollow glass beads are micron-level hollow closed spheres with low density, high strength and low thermal conductivity. They are used in elastomers such as glue and have the functions of heat insulation, weight reduction and increased resilience,

Learn More

Hollow glass beads to add rubber, can greatly reduce the proportion of shoes, shoes more comfortable.

Learn More