News

Effect of Hollow Glass Sphere on Adhesive Viscosity and the Solution of "Thickening" Phenomenon

Release time:

2022-10-17

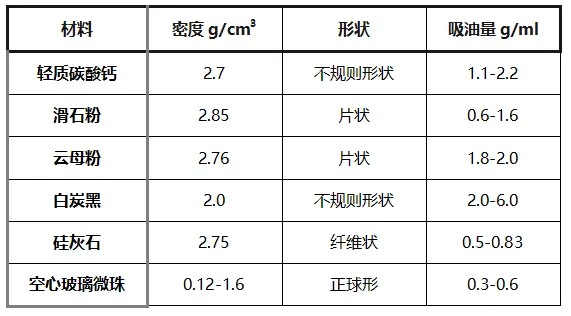

Viscosity is a manifestation of the fluidity of the adhesive, the addition of inorganic mineral fillers will increase the viscosity of the adhesive, and the degree of increase in viscosity is related to the type, shape and amount of minerals. If the particle size of inorganic mineral filler reaches nanoscale, due to large surface area, narrow particle size distribution and high oil absorption value, the viscosity of adhesive increases obviously. Flaky, fibrous, needle-shaped fillers have large interparticle porosity, and their oil absorption value is usually higher than that of spherical particles, which has a great influence on the viscosity of adhesive. The surface of fillers such as calcium carbonate, fumed silica and mica powder is rough, which makes the adhesive difficult to flow and the viscosity increase obviously.

Influence Factors of 1. Fillers on Adhesive Viscosity

The influence factors of filler on the viscosity of adhesive mainly have the following four aspects:

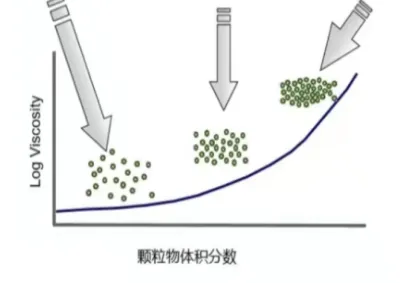

Volume fraction of 1.1 filler

The greater the volume fraction of the filler, the greater the flow retardation, the more difficult the flow, the greater the viscosity of the adhesive.

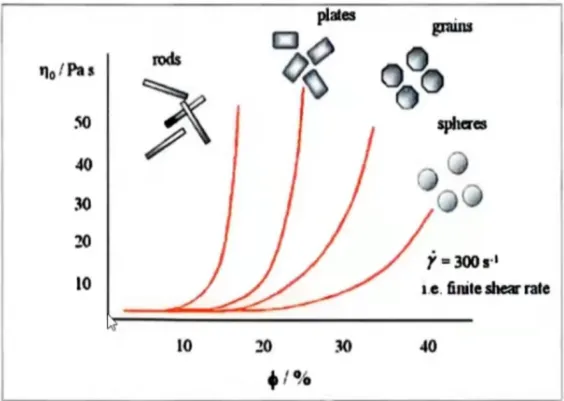

1.2 particle shape

Adhesives formed from uniformly sized spherical particles have a lower viscosity; adhesives formed from irregularly shaped particles generally have a higher viscosity. As the aspect ratio of the filler particles increases, the adhesive viscosity increases.

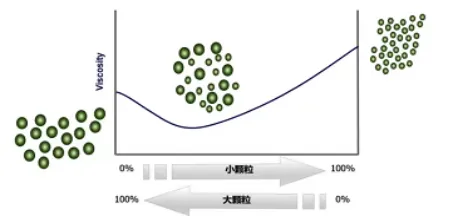

1.3 particle size distribution

In the case of the same addition ratio, the smaller the particle size of the filler, the greater the viscosity of the adhesive; on the contrary, the larger the particle size, the smaller the viscosity of the adhesive. Within a certain particle size distribution, there are both small particle size particles and large particle size particles, and the small particle size particles fill the gaps of the large particle size particles, and the adhesive viscosity is the smallest.

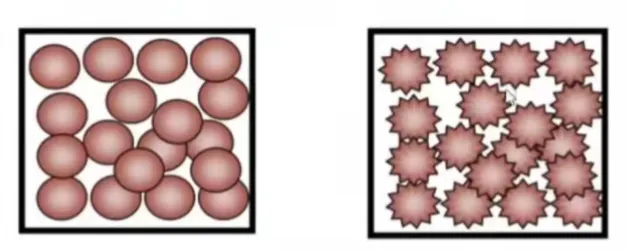

1.4 surface roughness

Generally, the coarser the filler particles, the greater the resistance to flow, the more difficult it is to flow, and the greater the viscosity of the adhesive.

Effect of 2. Hollow Glass Sphere on Adhesive Viscosity

Hollow Glass Sphere are normal spheres with smooth surface, have the smallest specific surface area, have a low oil absorption value, and have a certain particle size distribution. Compared with other fillers, Hollow Glass Sphere have the least effect on the viscosity of the adhesive.

Table 1 Part of the packing oil absorption value

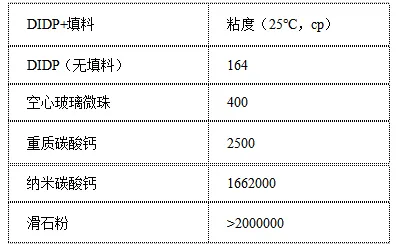

When the same volume fraction filler is added, the Hollow Glass Sphere have the smallest influence on the viscosity of the adhesive. The following is the comparison of the viscosity values after adding different fillers in DIDP.

Causes and Solutions of "Thickening" of 3. Hollow Glass Microspheres

3.1 Reasons for "Thickening" of Hollow Glass Microspheres

The thickening of Hollow Glass Sphere in adhesives has the following conditions:

1) Add directly in the original adhesive formula;

2) Replace part or all of the filler in the original adhesive;

3) Replace the specifications of Hollow Glass Sphere;

4) Replace Hollow Glass Sphere from different manufacturers.

In view of the thickening phenomenon of the above several situations, the possible reasons are as follows:

1) Hollow Glass Sphere as a filler added to the original adhesive, equivalent to increase the proportion of inorganic filler in the adhesive, will inevitably increase the viscosity of the adhesive. However, compared with other fillers, the effect of Hollow Glass Sphere on the viscosity of the adhesive is minimal, as we can see from the comparison in Table 2;

2) If other fillers are replaced according to the mass fraction, the viscosity of the adhesive will inevitably increase. Because of the low density of Hollow Glass Sphere, the same quality, Hollow Glass Sphere than other filler volume is much larger;

3) After replacing the specifications of the hollow glass microspheres, the volumes of products of different specifications are different under the same quality;

4) the same specifications of products, different manufacturers of Hollow Glass Sphere particle size distribution differences; the same specifications of products usually refers to the same product density, the same quality, if there is a difference in particle size distribution, and thus the volume is different, the same mass fraction of products oil absorption value will be different.

Generally speaking, a smaller particle size means that the same quality of microbead products have more particles, the distribution of particles in the matrix is wider, and the dispersion is more uniform, so that the adhesive after the spheres is added has more homogeneous and Better performance; but smaller particle size will also make the product have a larger specific surface area, the oil absorption rate of the product will also increase, and the viscosity of the adhesive will also increase.

The Solution of "Thickening" of 3.2 Hollow Glass Sphere

Through the analysis of the thickening phenomenon, we can find the corresponding solutions for different situations:

1) adjust the adhesive formula, so that the components have the best compatibility;

2) Replace other fillers in the original adhesive with the same volume fraction (true volume);

3) Selecting Hollow Glass Sphere products with larger particle size can reduce the thickening phenomenon, but smaller particle size may get better product performance;

4) For products of the same density, adjust the particle size of Hollow Glass Sphere, usually large particle size can reduce the thickening phenomenon;

5) Appropriate surface treatment, such as coupling agent coating, can increase the compatibility of the adhesive and reduce the thickening phenomenon.

Adjusting the product formula is an effective way to adjust the viscosity of the adhesive, and selecting the appropriate specifications of the Hollow Glass Sphere is also helpful to the adjustment of the viscosity of the adhesive. For the same density of the product, HOLLOWLITE can adjust the size of the particle size and the appropriate surface treatment. HOLLOWLITE is the production of Hollow Glass Sphere professional manufacturers, can be customized to produce the required indicators of products.

Related News