News

The Application of Hollow Glass Sphere in Silicon Sealants

Release time:

2024-08-20

Cost control, product research and development and technological innovation are several key aspects to the current manufacturing industry. Among them, cost control determines the living space of enterprises. Reducing costs and expanding sales are two ways to control costs and generate profits. Under the background of global economic integration and the continuous development of e-commerce, product prices are becoming more and more transparent. How to choose effective cost reduction programs is an important topic for enterprise development.

Hollow Glass Sphere Is a kind of micron-sized hollow glass sphere with a smooth surface.

It has a variety of properties such as low density, high strength, low thermal conductivity, electrical insulation, high temperature resistance, acid and alkali resistance, and has good fluidity and chemical stability, it is known as "the 21st century space age material". The application of hollow glass sphere in composite materials can bring innovative application solutions to reduce cost and increase efficiency in manufacturing industry.

The Cost reduction advantage of hollow glass sphere

The cost of the product is usually reduced by adding as much filler as possible. The filler is usually inorganic powder, which is cheap in itself, which can not only improve product performance, but also reduce the relative use of resin, thereby reducing the cost of the product. Fillers are usually with high density, and the use of a large number of fillers will increase the density of the product while reducing the cost of the product, and the performance of the product may also be affected. Since the density of hollow glass sphere is very low, when applied to adhesives, only need to add very little mass (mass ratio of 1%-2%) can reduce the cost of the product, the product density is reduced, and the product viscosity will not increase significantly.

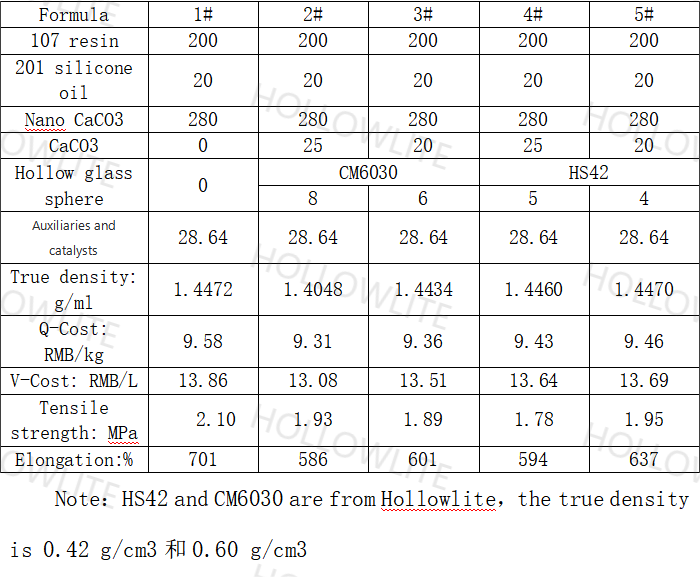

Taking the sealant with a density of 1.45g/ml as an example, hollow glass sphere HS42 and CM6030 were used for the experiment, and the scheme was as follows:

Through this formula design, the quality cost and volume cost are reduced, the density of the product is basically unchanged, and the mechanical properties remain good.

Related News