News

Advantages and Suggestions of Hollow Glass Sphere Used in Rubber Products

Release time:

2023-07-20

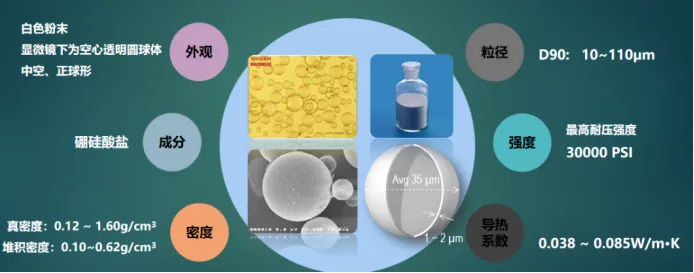

Hollow Glass Sphere, as a "space material in the 21st century", play its unique function in many fields.

01

Adding Hollow Glass Sphere to rubber products can bring many advantages:

1, weight reduction

Rubber products are also developing in the direction of lightness and durability, especially the rubber soles with mature application of spheres at present, from the regular density of about 1.15g/cm³ to 1.0g/cm³ (commonly known as "floating on the water") by adding 5-8 parts of spheres. At present, customers with certain research and development capabilities can achieve a density of 0.9 or even 0.85g/cm³ by adding spheres, thus greatly reducing the rubber density, the shoe type is the same as before, and the weight is reduced by about 20%.

2. Thermal insulation

The hollow structure of the Hollow Glass Sphere gives the Sphere low thermal conductivity, and it can play a good thermal insulation effect when added to the rubber material as a low thermal conductivity filler, such as in the thermal insulation pad, thermal insulation board and other products.

3. Sound absorption and noise reduction

The inside of the Hollow Glass Sphere is a thin gas, and the sound wave will be weakened in this part, which has a good sound absorption and noise reduction effect under a certain amount of addition.

4. Good dimensional stability

The Hollow Glass Sphere substrate is a glass material with a low thermal expansion coefficient, and has good dimensional stability when subjected to cold and thermal shock. Adding to the rubber material will give the product better dimensional stability.

02

Recommendations for use in the machining process:

1. The processing equipment for rubber products is generally a mixer, an open mill, a single screw extruder, etc. Because the walls of the Hollow Glass Sphere are rigid particles made of glass, they will be partially broken under the action of mechanical shearing force. After the beads are broken, they will lose their unique functionality.

2, Hollow Glass Sphere have different models and corresponding parameters, according to different equipment and product requirements to choose the right bead products is extremely important, Saint Wright recommend in rubber products using HL38, HL42, HL50, HS38, HS42.

3. When used in an internal mixer, the rotor shears the rubber material, and the Hollow Glass Sphere are inevitably subjected to shearing force. Therefore, it is recommended to reduce the time of Hollow Glass Sphere in the internal mixing as much as possible. It is recommended to add them at the later stage of internal mixing to ensure that the Hollow Glass Sphere can be evenly dispersed after 3-5min of internal mixing. On the open mixer, the roller spacing and the opening time have great influence on the crushing of beads; the overall shear force of the single screw extruder is small, and the influence on the Hollow Glass Sphere is relatively small. It is suggested that the extrusion temperature should be increased by 5 ℃, and the viscosity of the material should be reduced.

Related News