News

How to choose the right beads in rubber

Release time:

2023-11-24

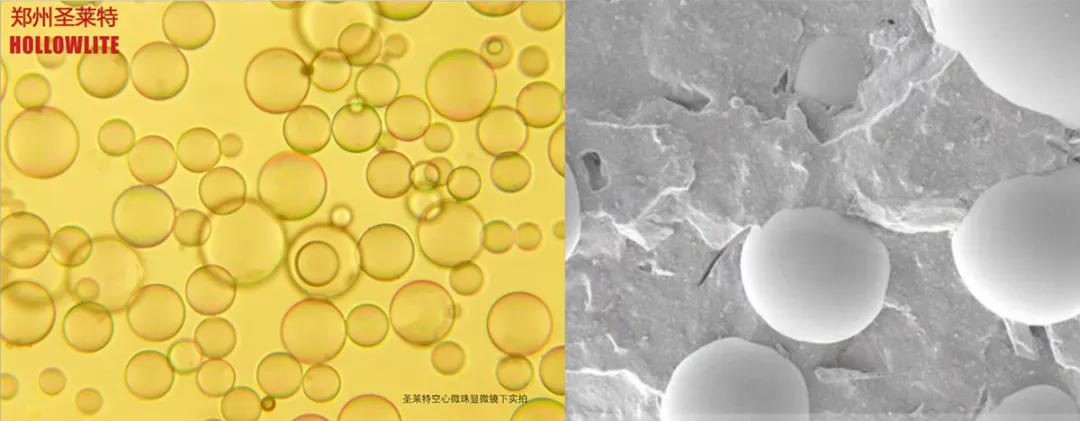

The use of Hollow Glass Sphere in rubber products has given the functions of lightweight , heat insulation, sound absorption and noise reduction, good stability, and improved processability, which has expanded the new technical direction and application space for the rubber industry. The application is more extensive.

Hollow Glass Sphere need to be selected according to the application requirements and actual processing conditions. Three basic indicators of Hollow Glass Sphere:

The true density refers to the true density of the Hollow Glass Sphere. The Hollow Glass Sphere is a closed sphere, and its true density is the density after removing the gaps between the spheres. The true density directly affects its weight reduction effect on rubber.

Particle size refers to the spherical diameter of Hollow Glass Sphere, generally expressed by D50 and D90. The size of the particle size will affect the surface quality and tear tensile properties of rubber products.

The compressive strength refers to the limit value of the hollow spheres of the Hollow Glass Sphere when they are subjected to pressure. The crushed spheres become glass fragments and lose the characteristic of low specific gravity.

Examples

As shown in the following figure, 8 parts of beads with 0.35 specific gravity are added to the rubber formula (fig. 1). theoretically, the specific gravity is reduced by 13.7, and the rubber specific gravity is reduced from 1.1 to 0.949. if 30% crushing occurs in the actual processing process, the weight is reduced by only 8.98, and the rubber specific gravity is only 1.001 (fig. 2); At this time, the addition amount is also 8 parts of beads with 0.38 specific gravity, in actual processing, only 5% of the rubber is broken, the specific gravity of the rubber is reduced from 1.1 to 0.9724, and the weight reduction can reach 11.6 (Figure 3).

Figure 1

Figure 2

Figure 3

Processing of rubber

Rubber processing process is usually: mixing-open-vulcanization, in the process, the spheres will be subject to strong mechanical force, select the appropriate Hollow Glass Sphere on the application effect has a great impact.

Hollow Glass Sphere with lower specific gravity, higher strength and smaller particle size are used in rubber to make the product have better performance. HOLLOWLITE is committed to the development of high-performance Hollow Glass Sphere, to provide the industry with more cost-effective products, to help the rubber industry to reduce cost efficiency.

Related News