News

News

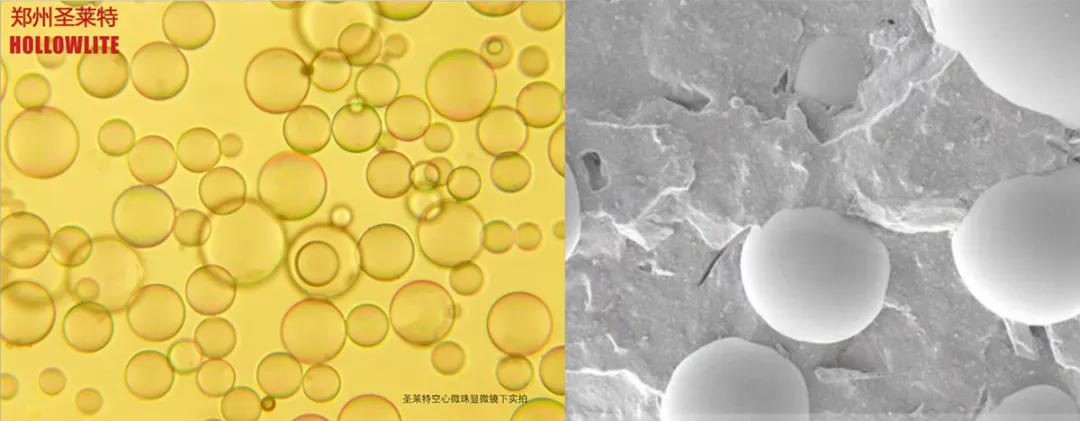

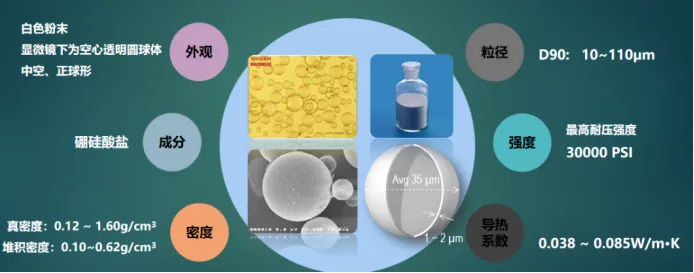

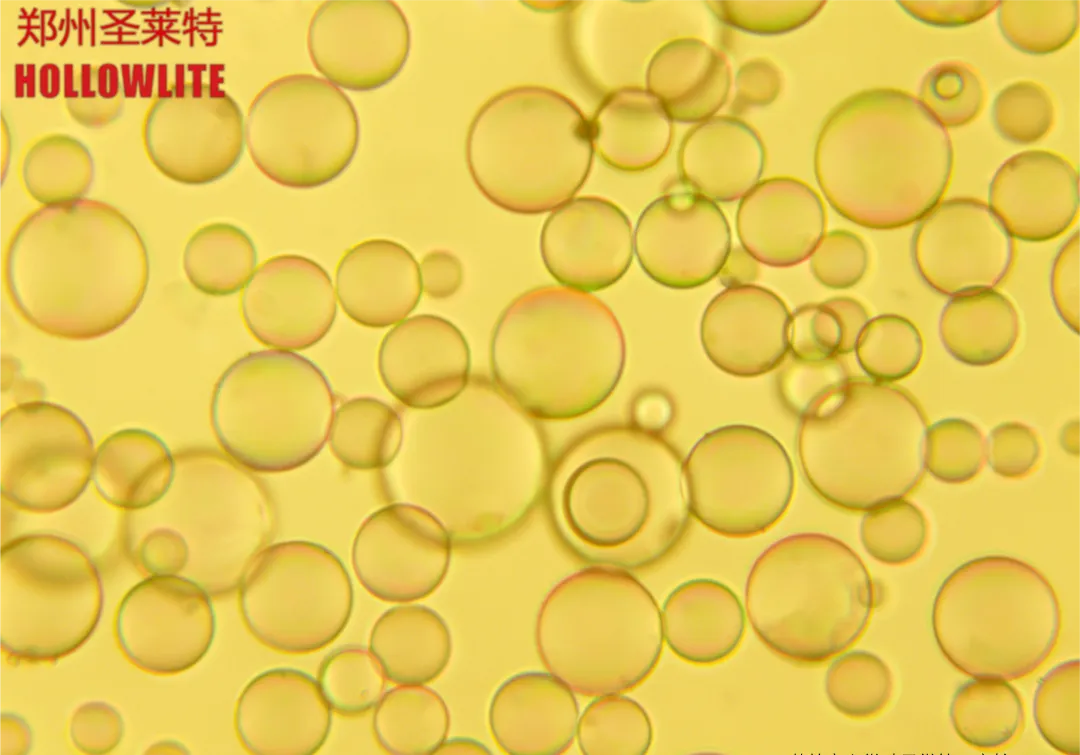

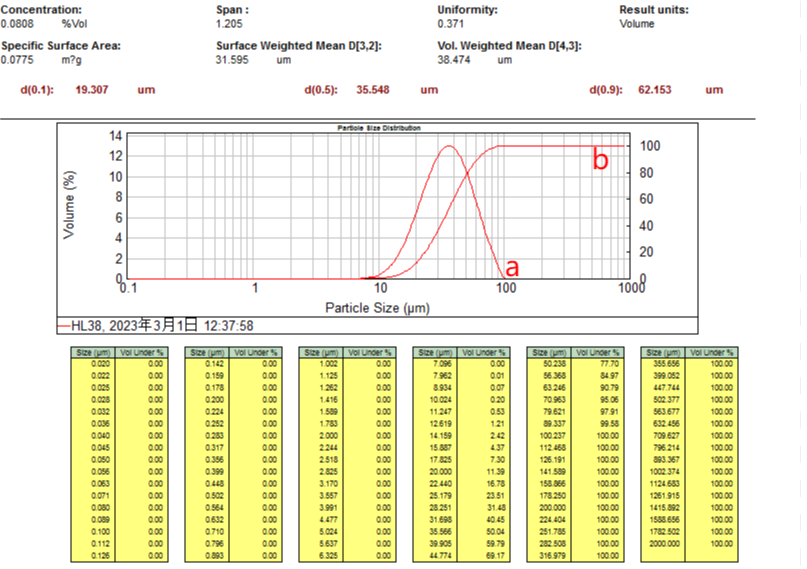

Unveiling the Versatility of HL Series Hollow Glass Spheres

2024-07-23

The First Forum on Application and Development Trend of New Automotive Materials in 2016

2024-04-27

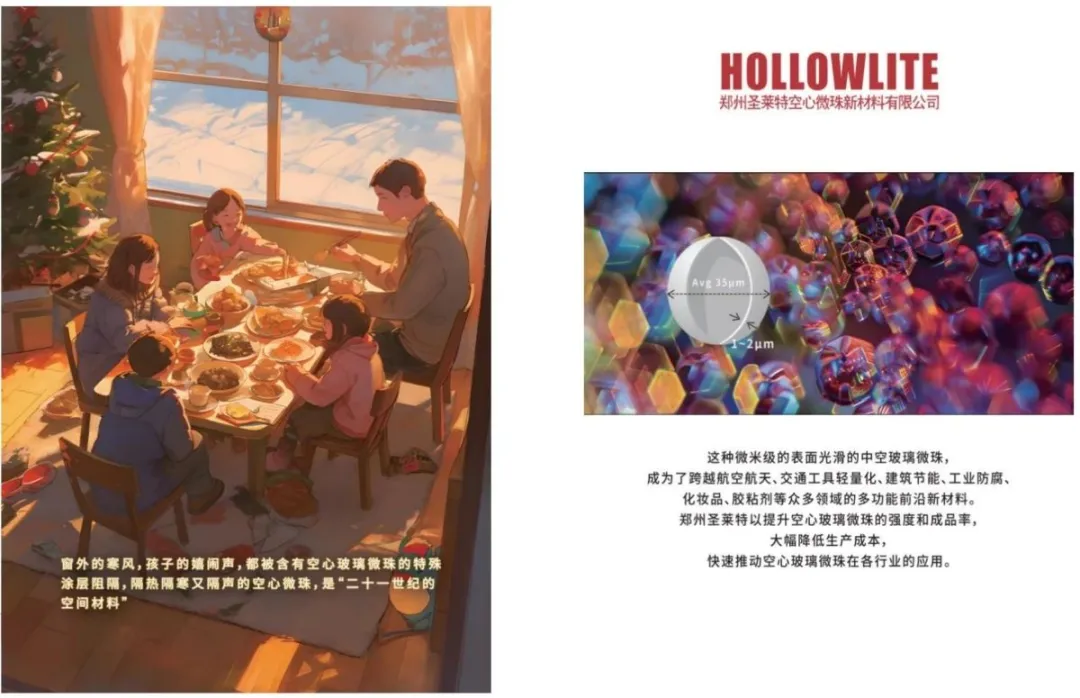

Science and technology change life,HOLLOWLITE let Henan more brilliant!

2024-03-03

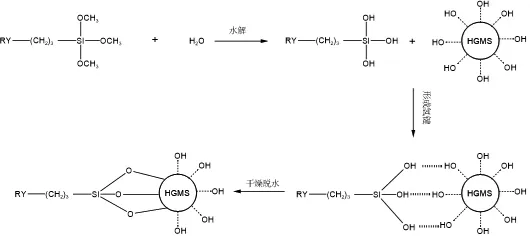

Surface Modification Principle of Inorganic Powder Materials

2023-12-15

How to choose the right beads in rubber

2023-11-24

Advantages and Suggestions of Hollow Glass Sphere Used in Rubber Products

2023-07-20

Hollow glass beads help the home appliance industry to reduce costs and increase efficiency

2023-06-08

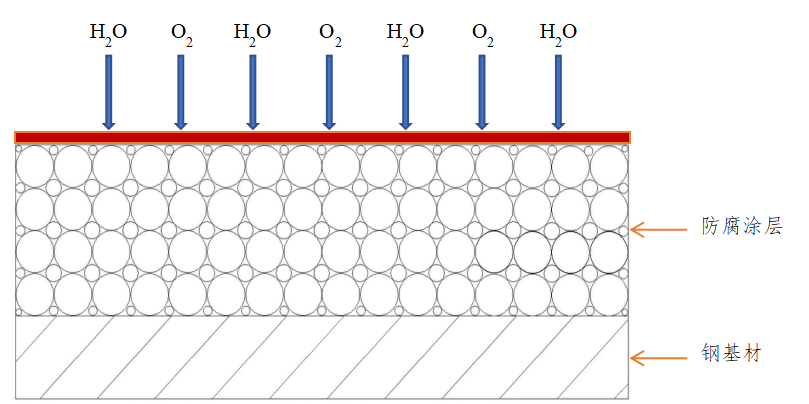

Application of Saint Wright Hollow Glass Microspheres in Thermal Insulation Coatings

2023-05-05

2023-03-21

Application of Hollow Glass Sphere in epoxy zinc-rich primer

2022-10-31

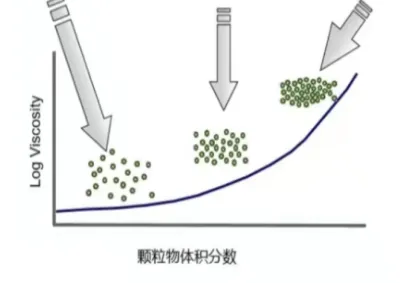

Effect of Hollow Glass Sphere on Adhesive Viscosity and the Solution of "Thickening" Phenomenon

2022-10-17

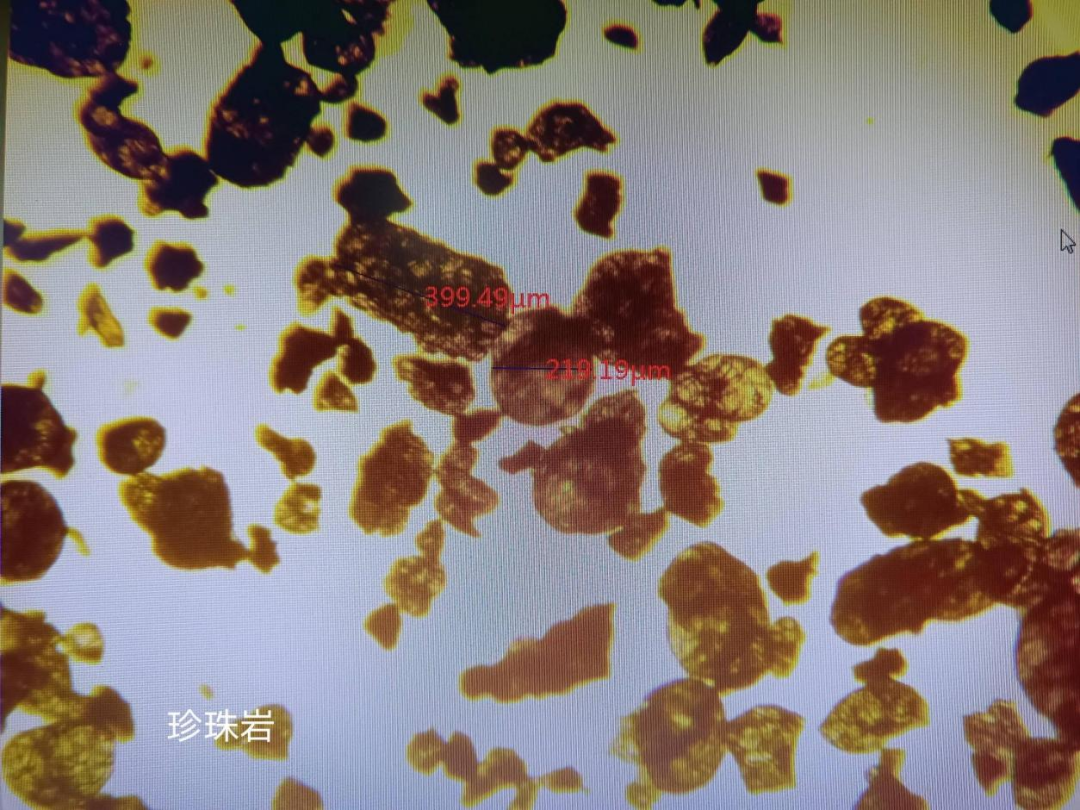

The difference between hollow glass beads and perlite, floating beads

2022-08-18